Peter Prints 3D

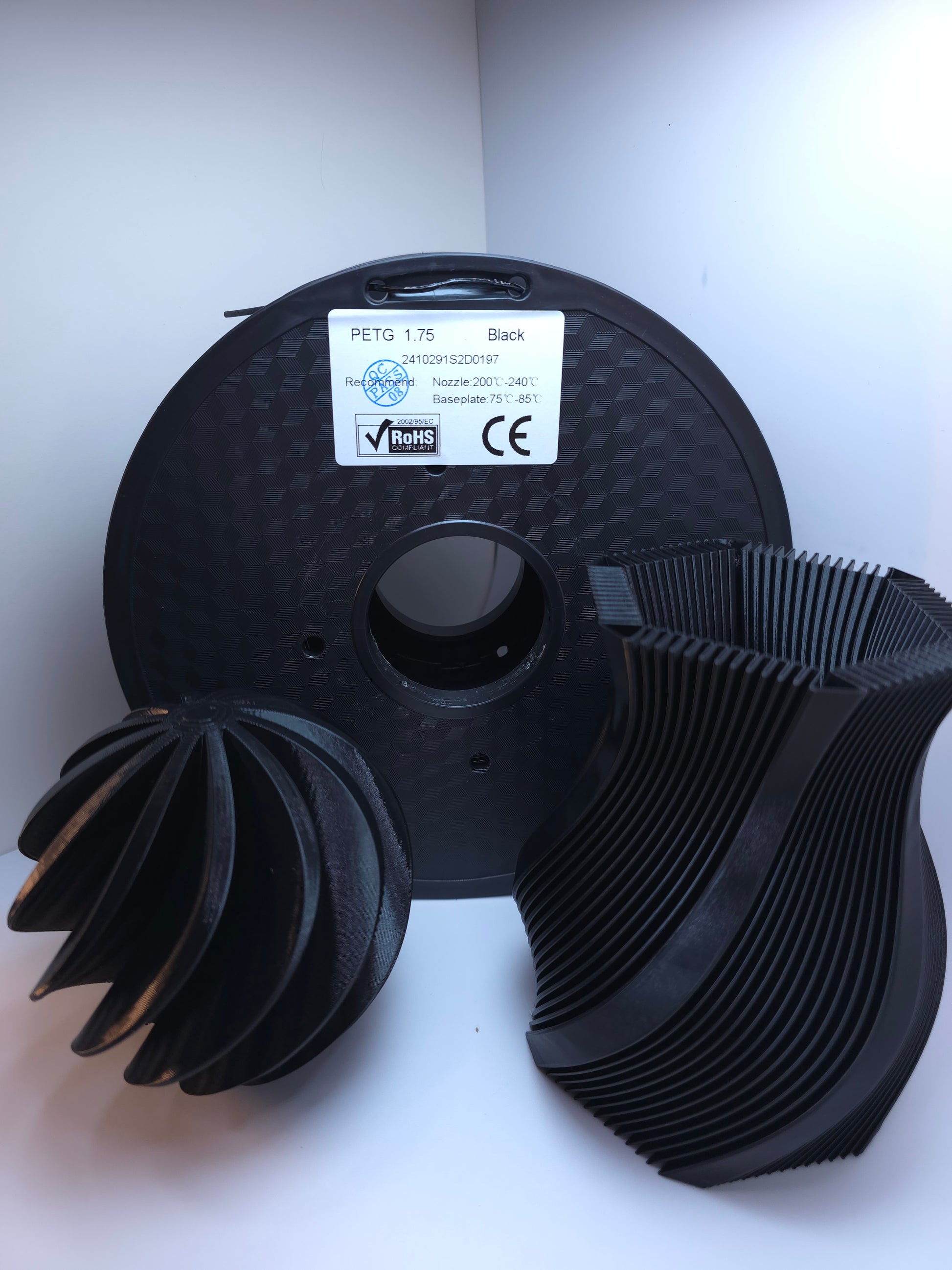

PETG Solid Colors 1.75mm - Peter Prints 3D

PETG Solid Colors 1.75mm - Peter Prints 3D

Couldn't load pickup availability

This is a filament I am offering for sale because I currently buy bulk filament for use in my 3D printing business, and thought it would be cool to offer up some of the colors I enjoy using.

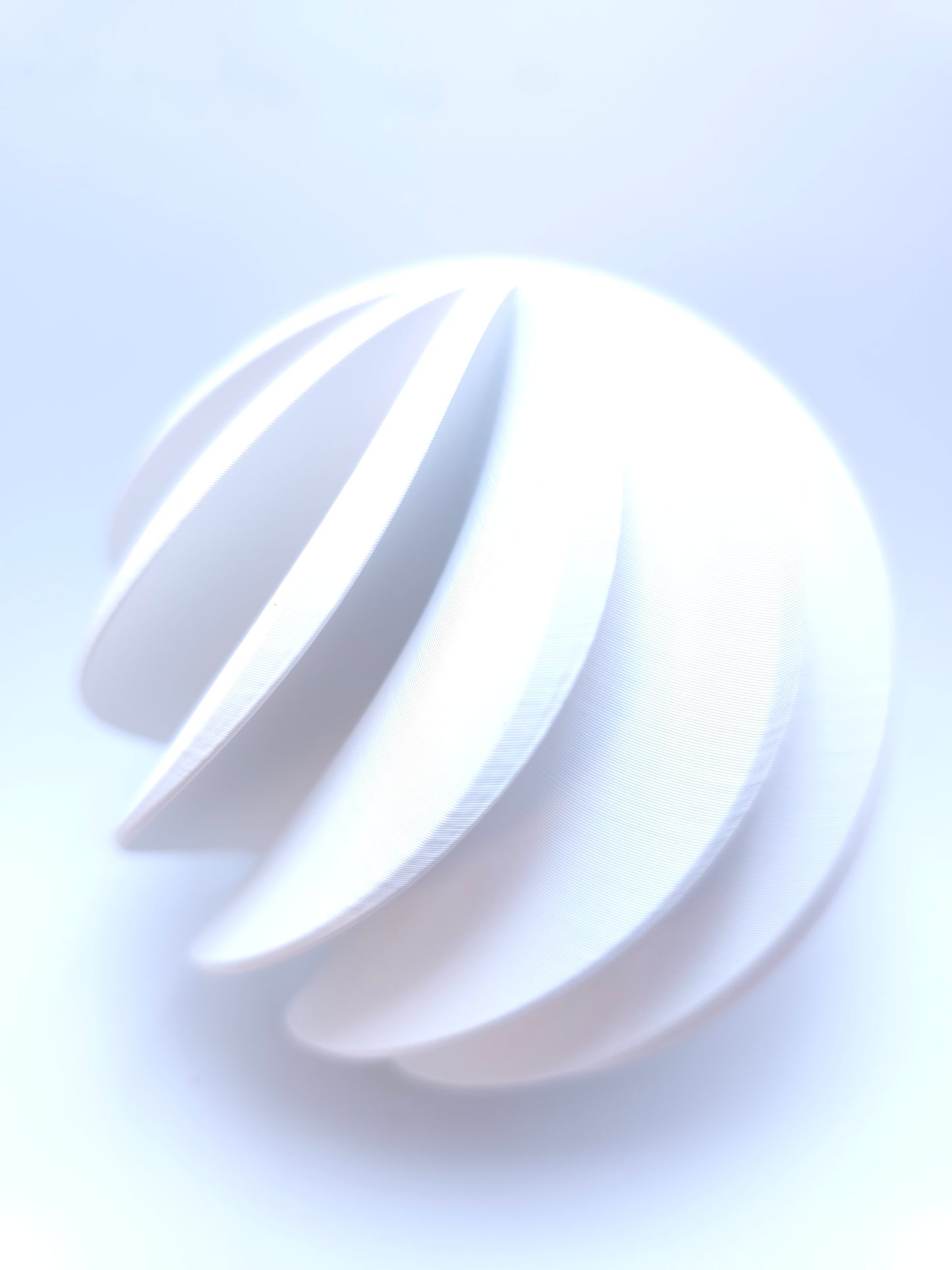

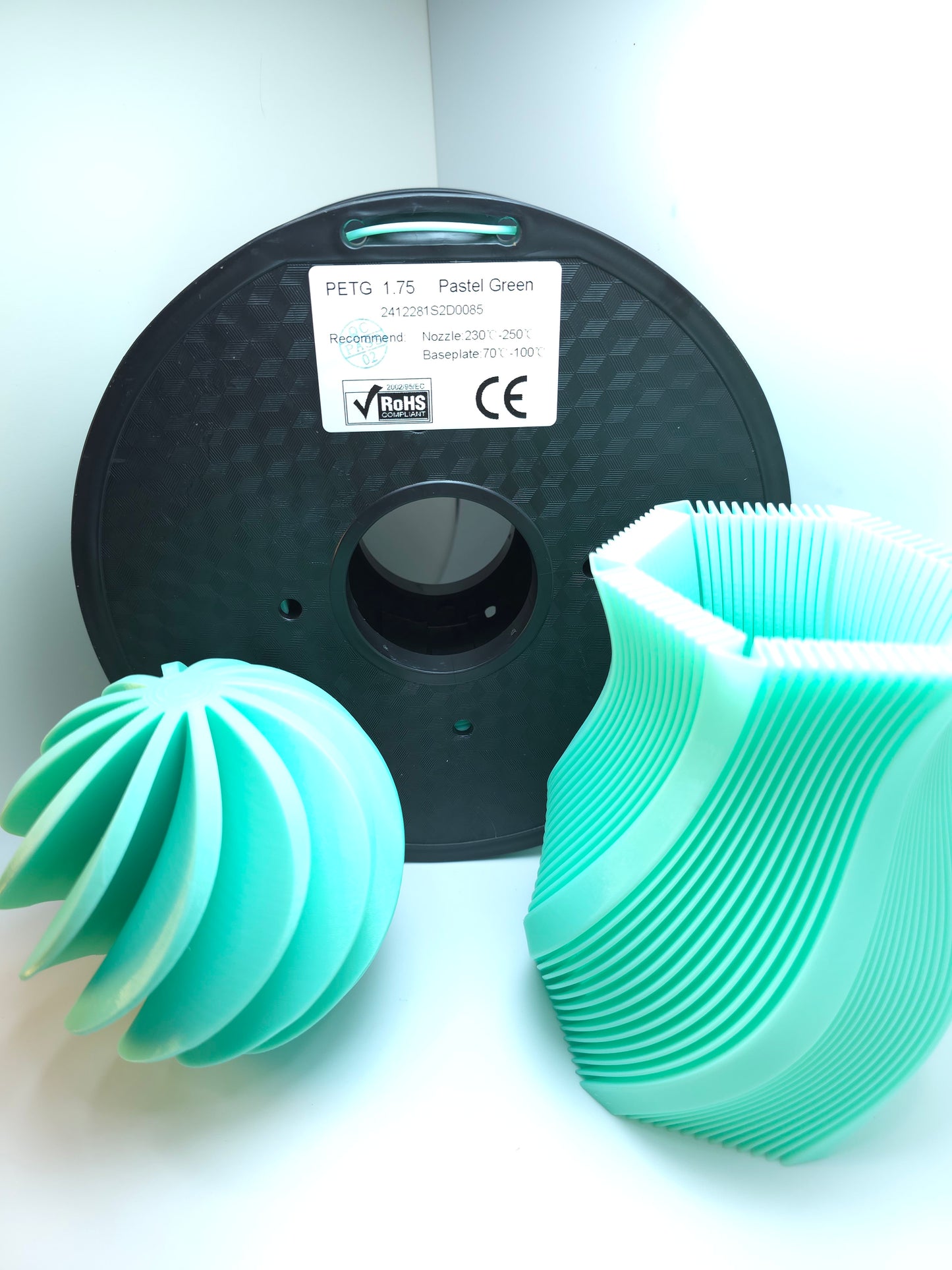

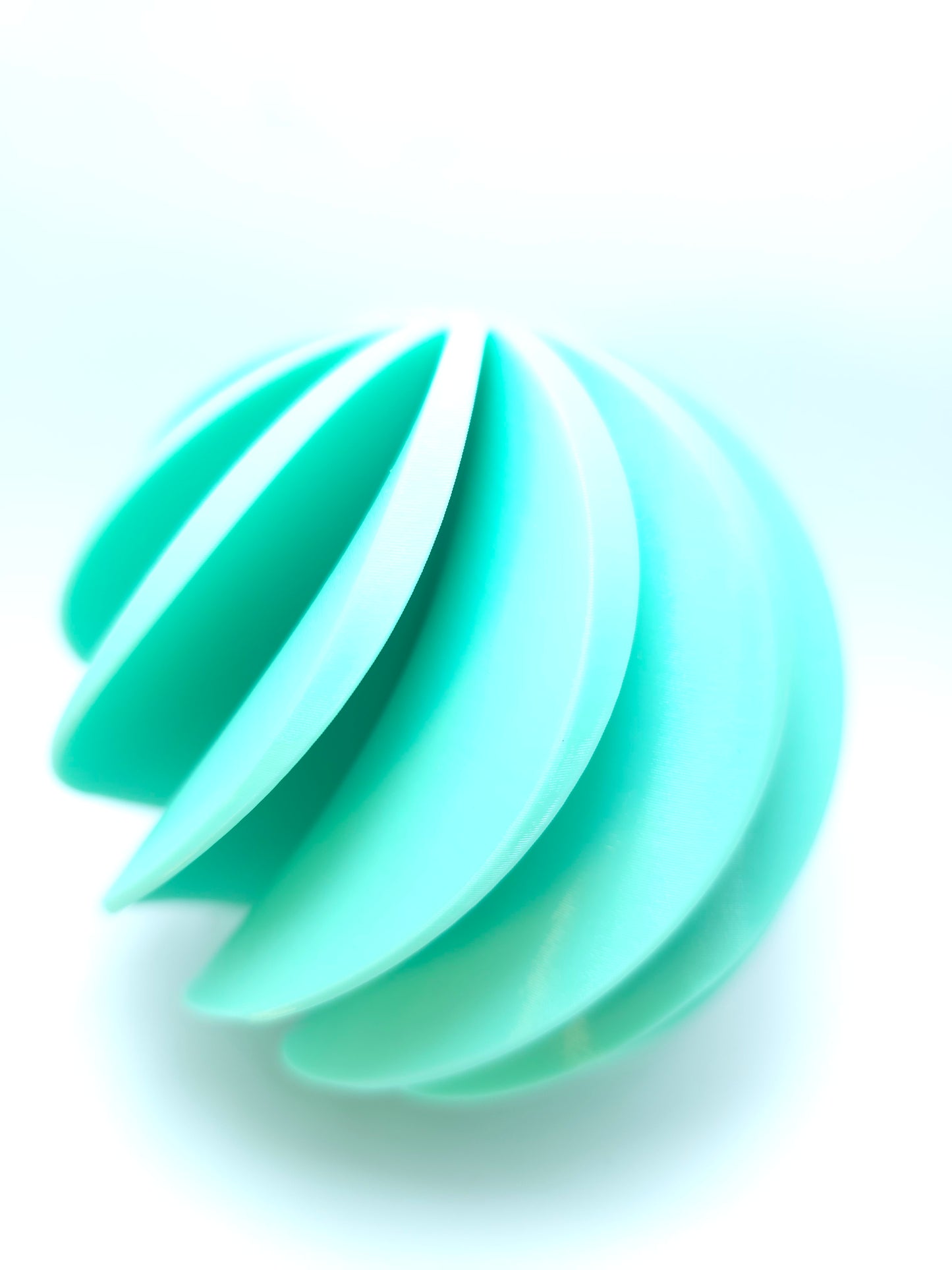

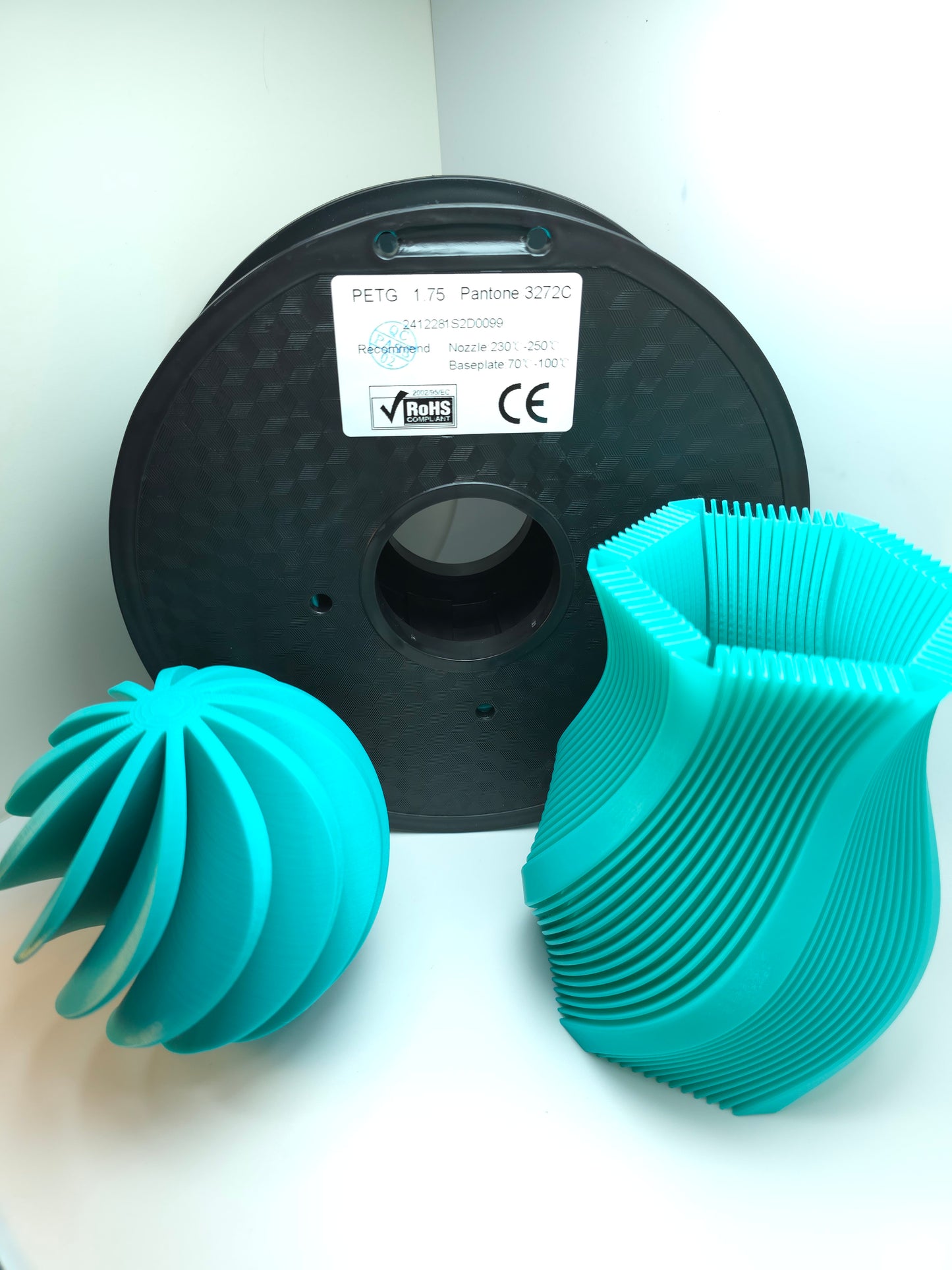

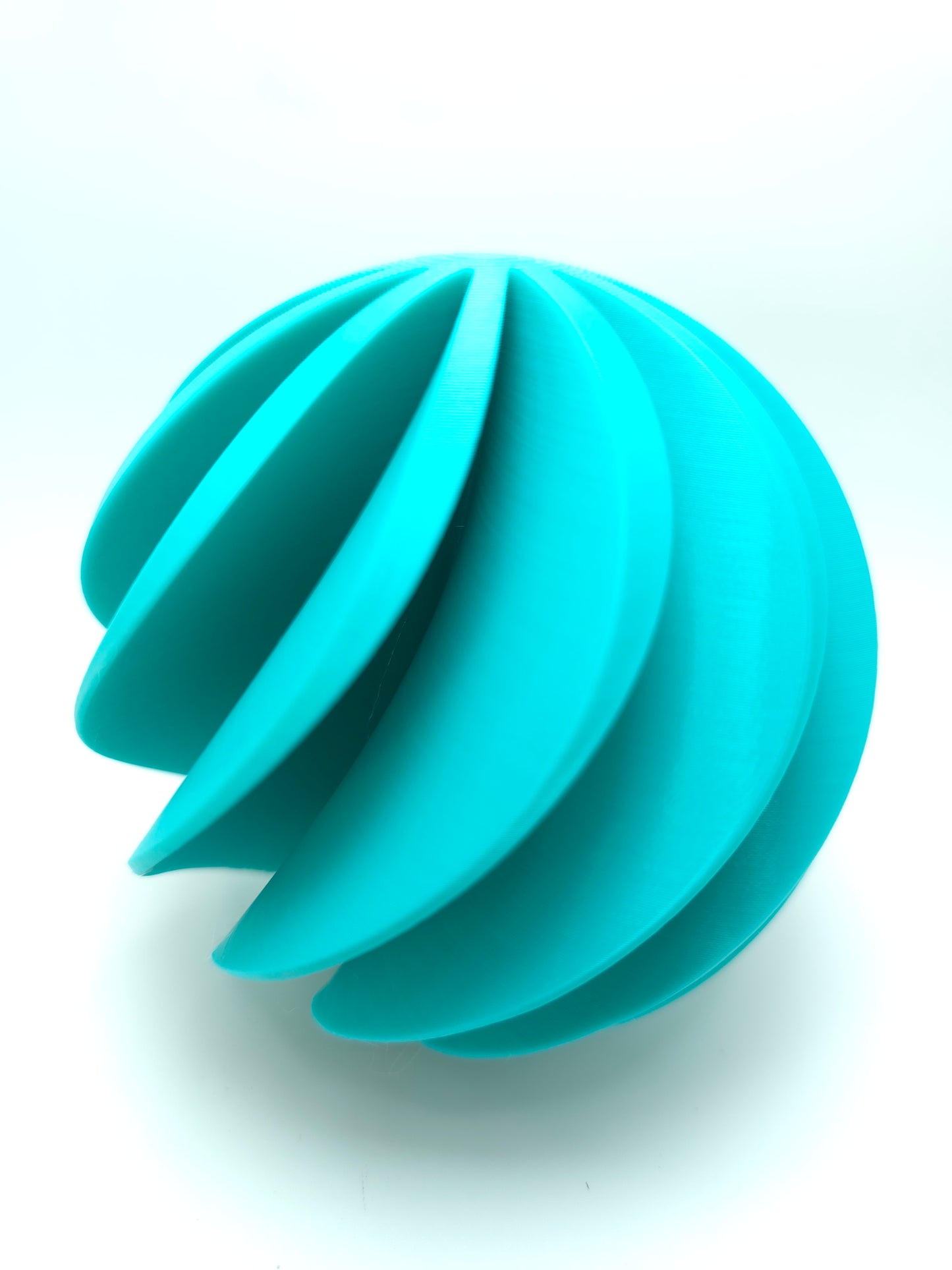

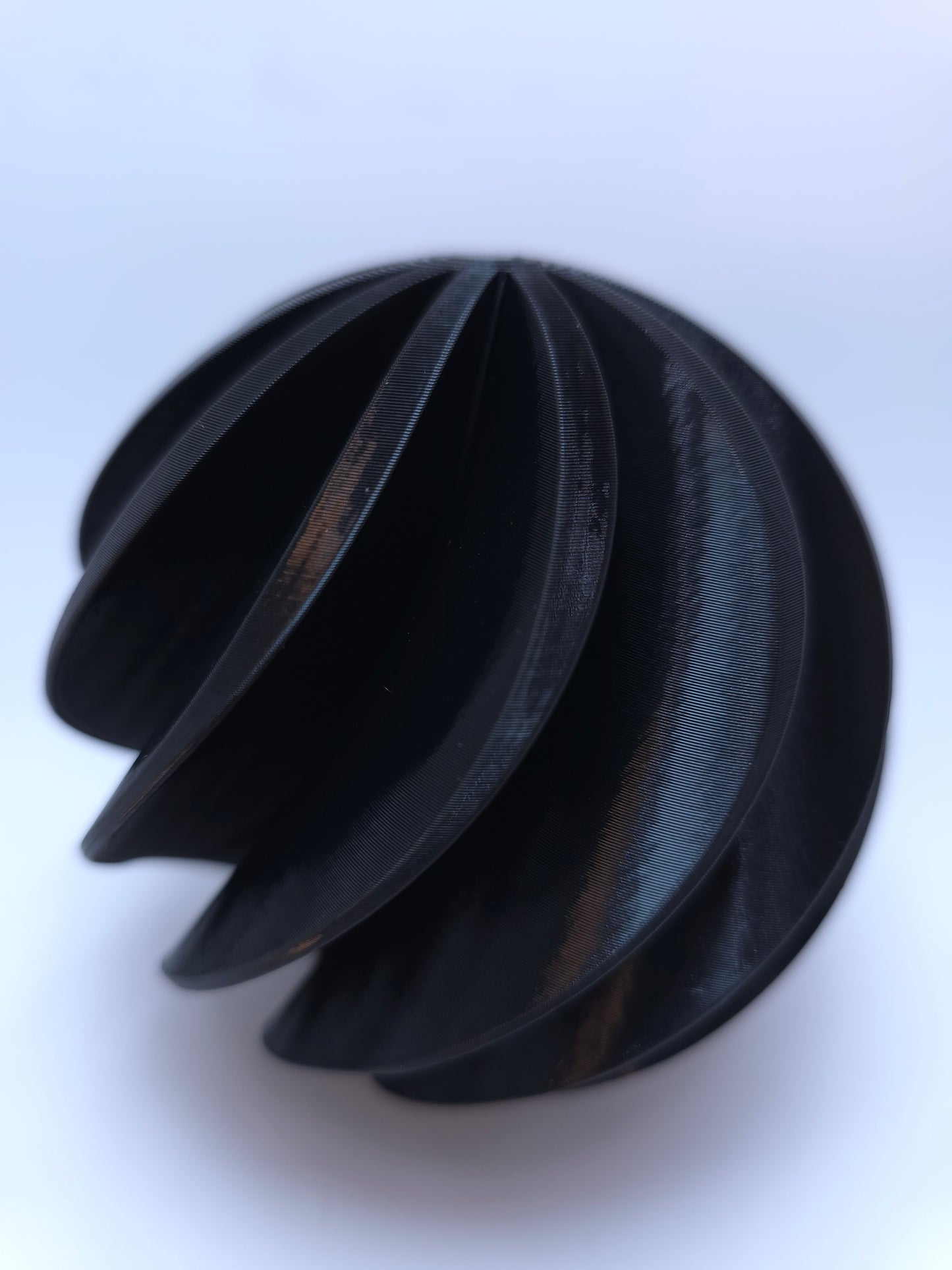

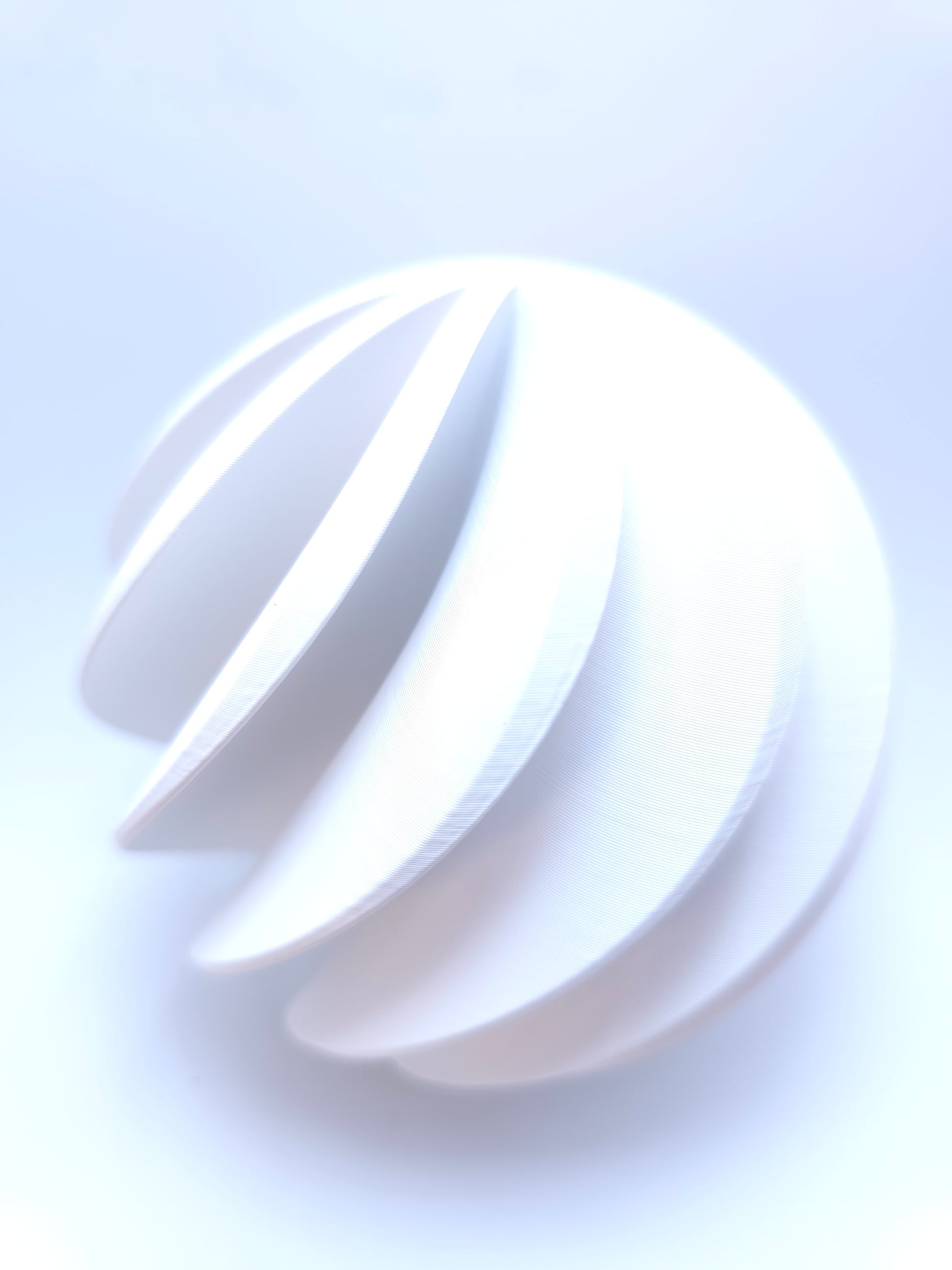

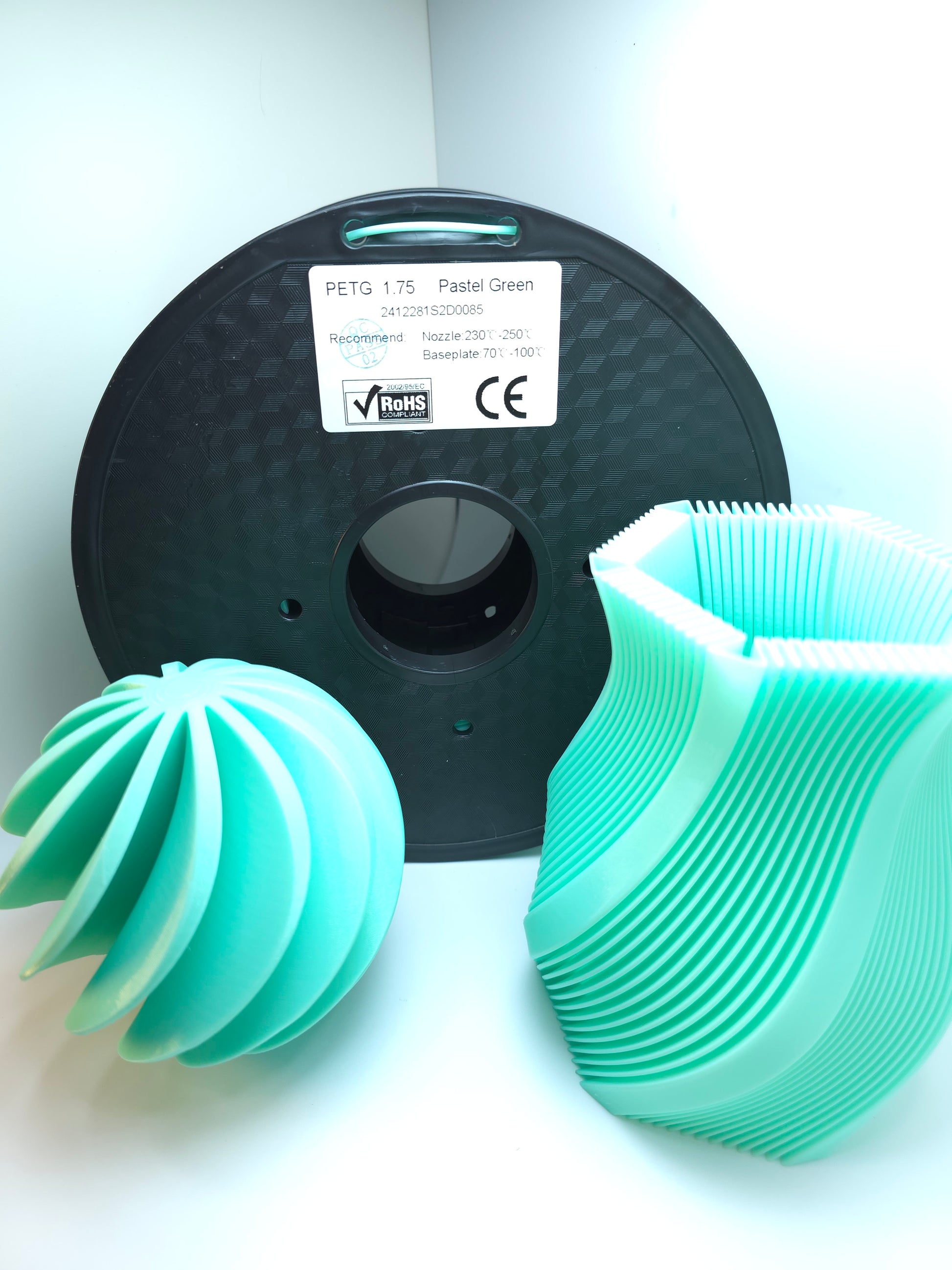

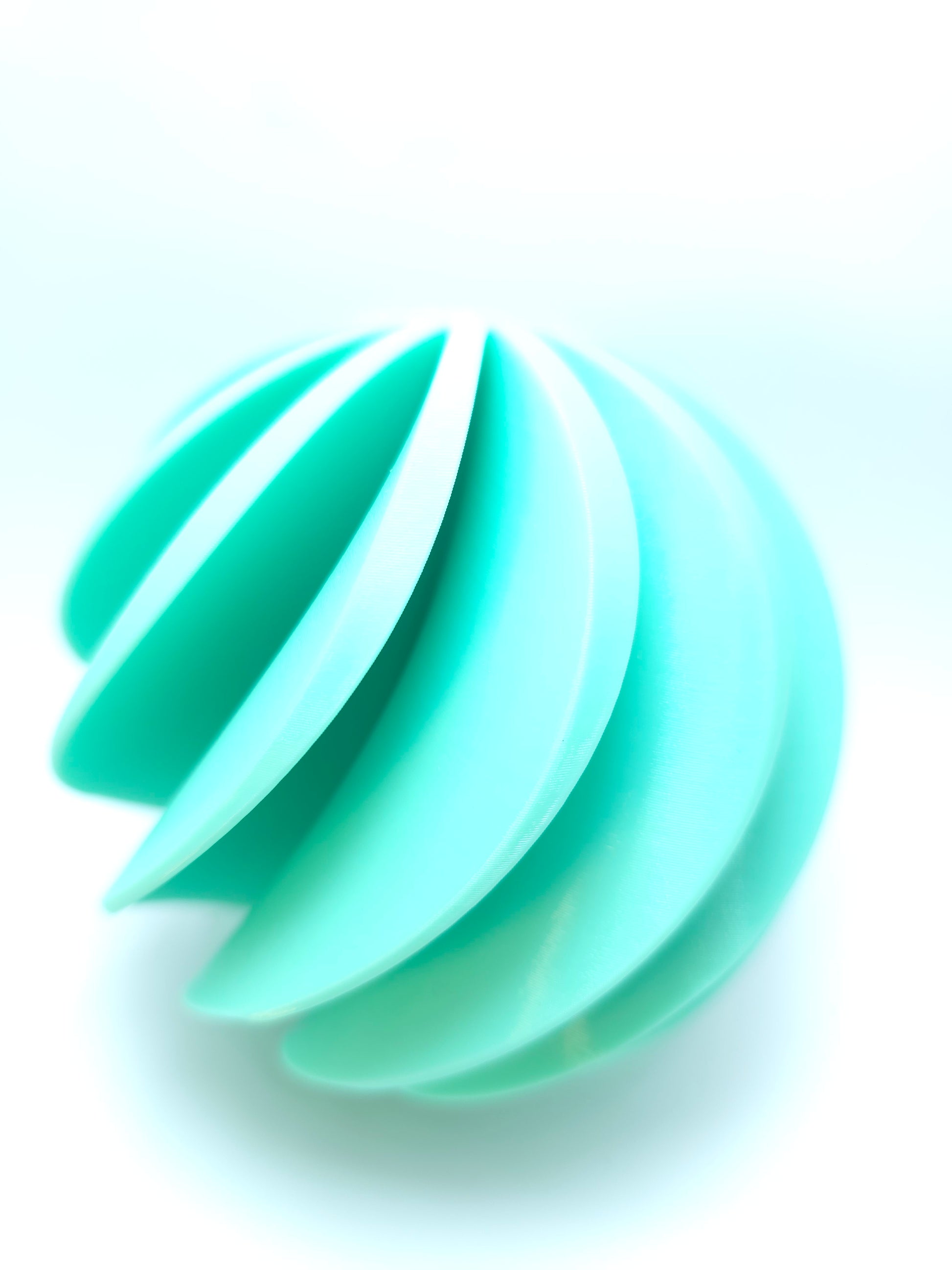

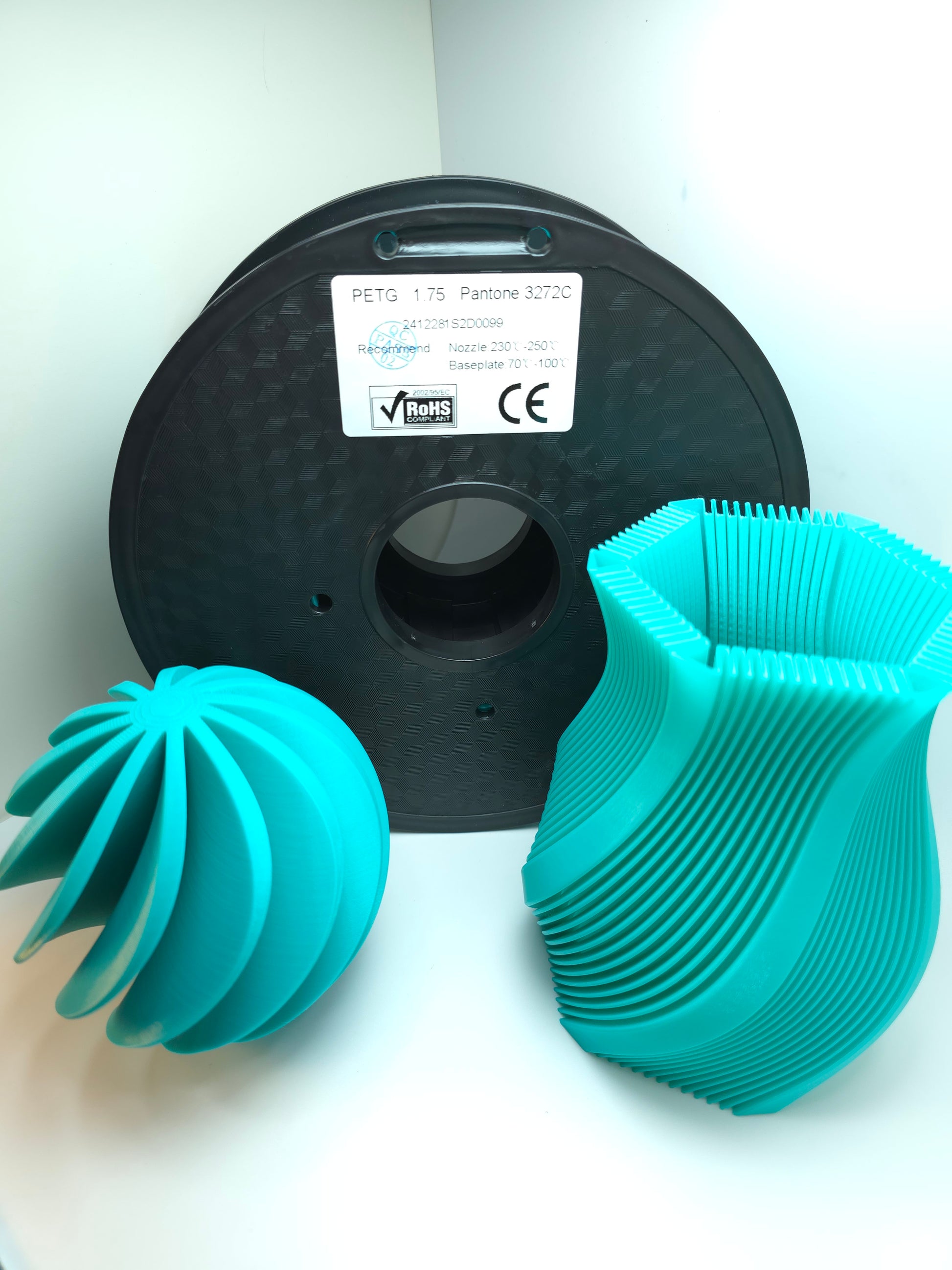

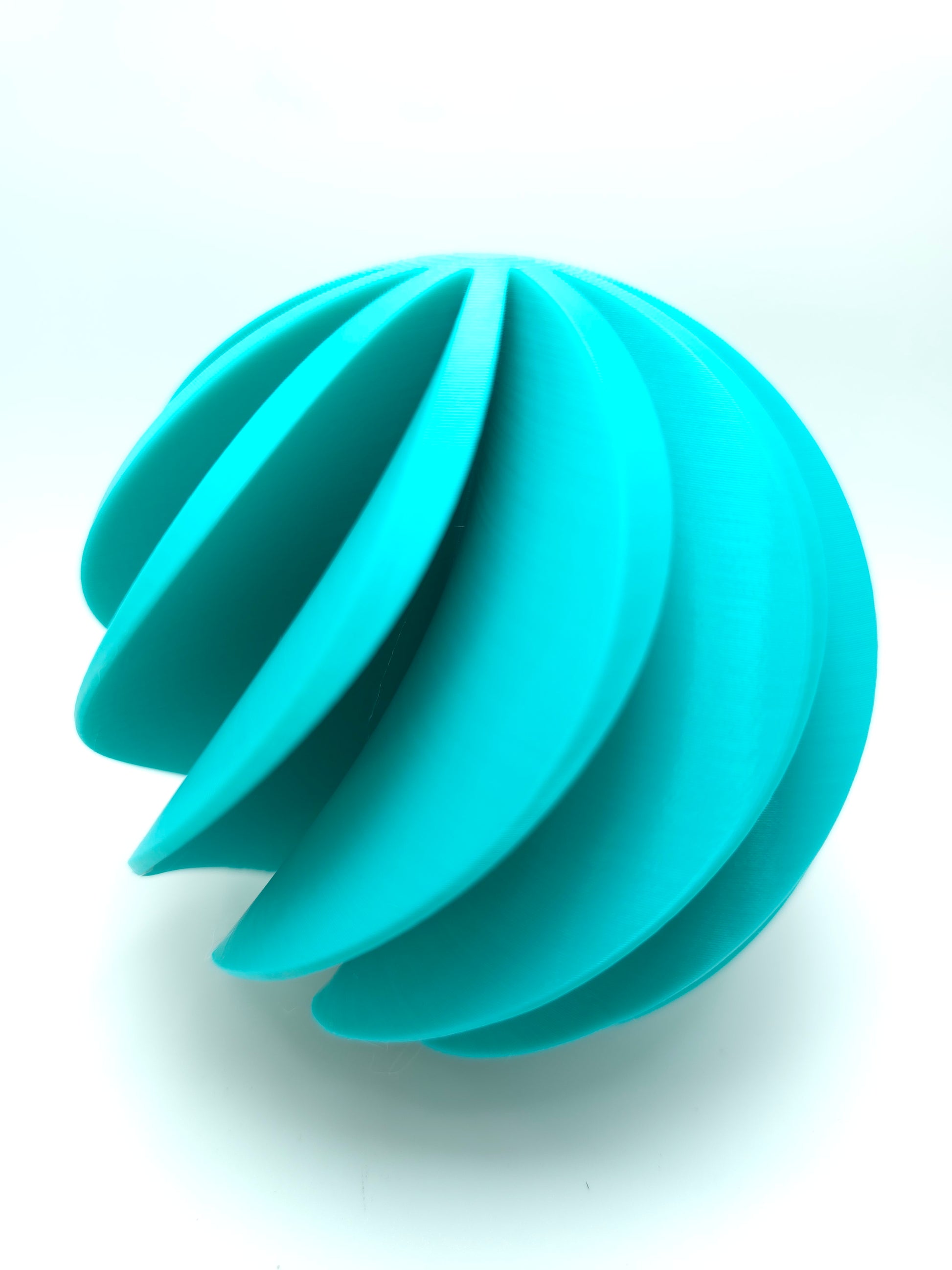

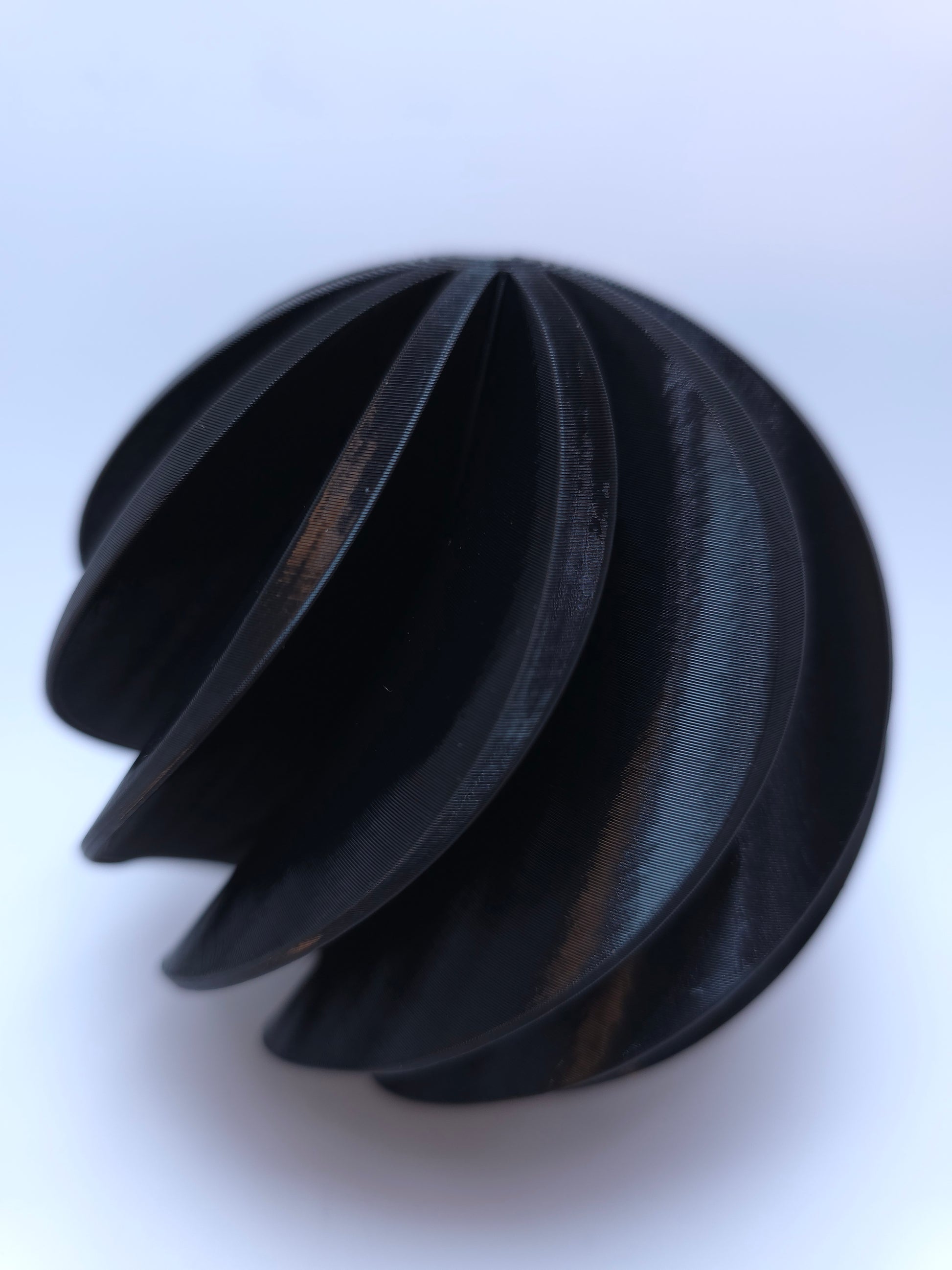

The photos show both a single vase-mode (single wall) print, which is the hexagonal vase, and also a spiral ball, which is a four wall print.

Check out my videos for more info about these and more filaments and their uses, properties, and aesthetics!

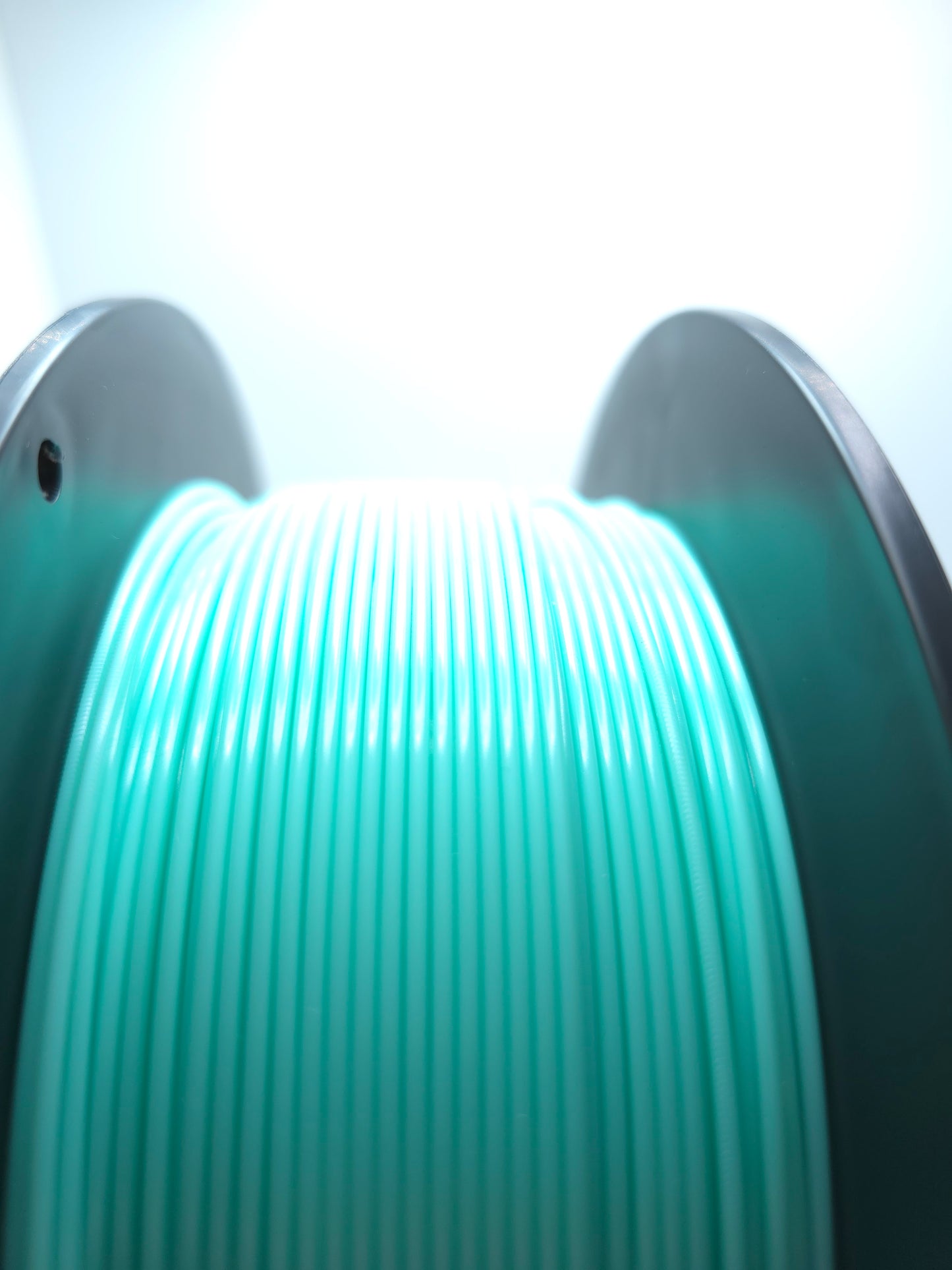

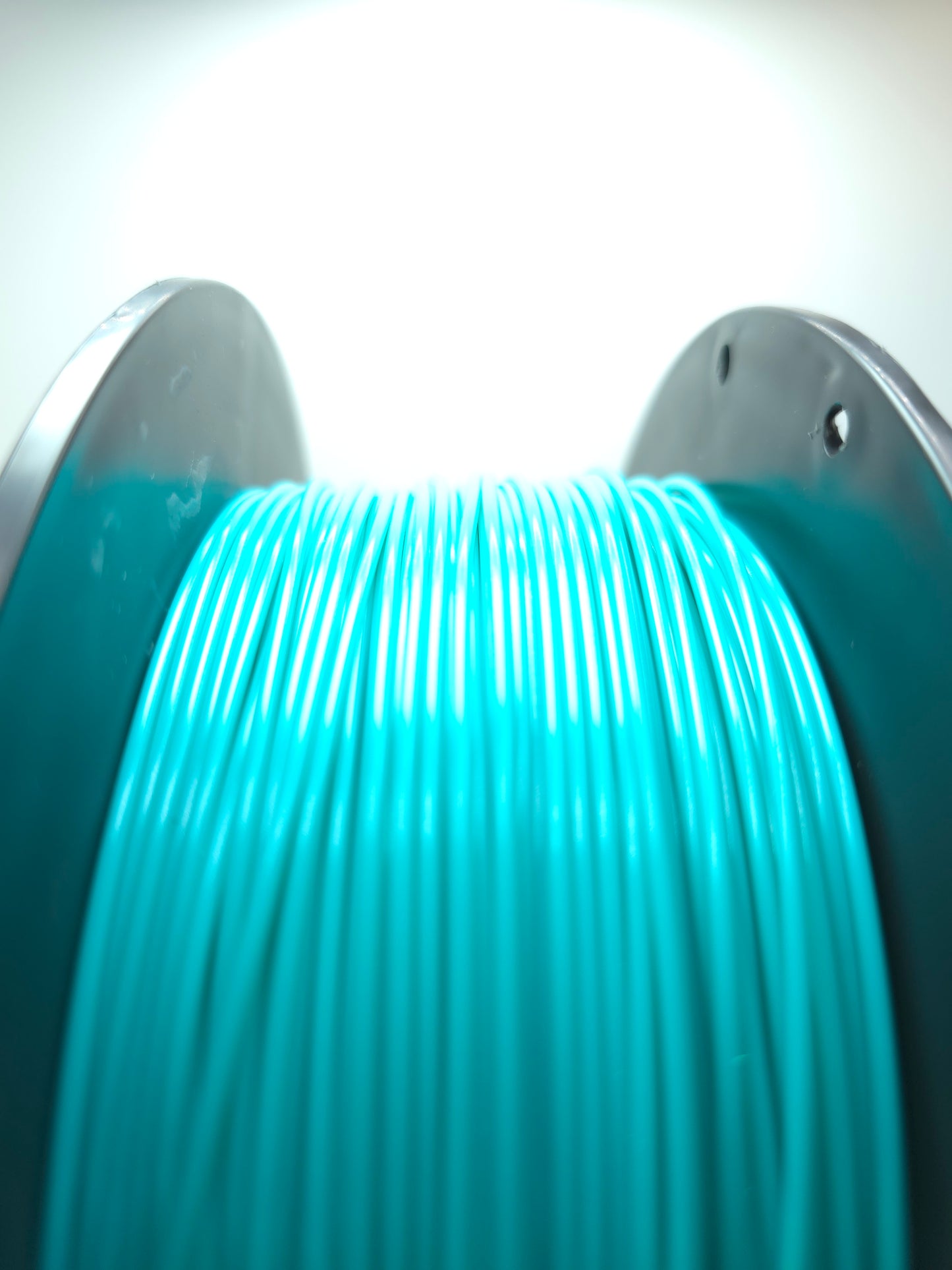

I adjusted every photo to show as close of a color match to each filament as I could. I intend to include print profiles and test prints with a few printers to showcase the filament under different conditions.

Overall, the PETG prints very much like most PETG profiles I am used to using, and I have had no problems printing with it thus far.

High-Quality PETG Filament has the advantages of both PLA and ABS filaments. Eco-friendly, odorless, and non-toxic. No cracking and warping. With good toughness, the printed model is firm and sturdy. The filament can bend repeatedly with high elongation at break.

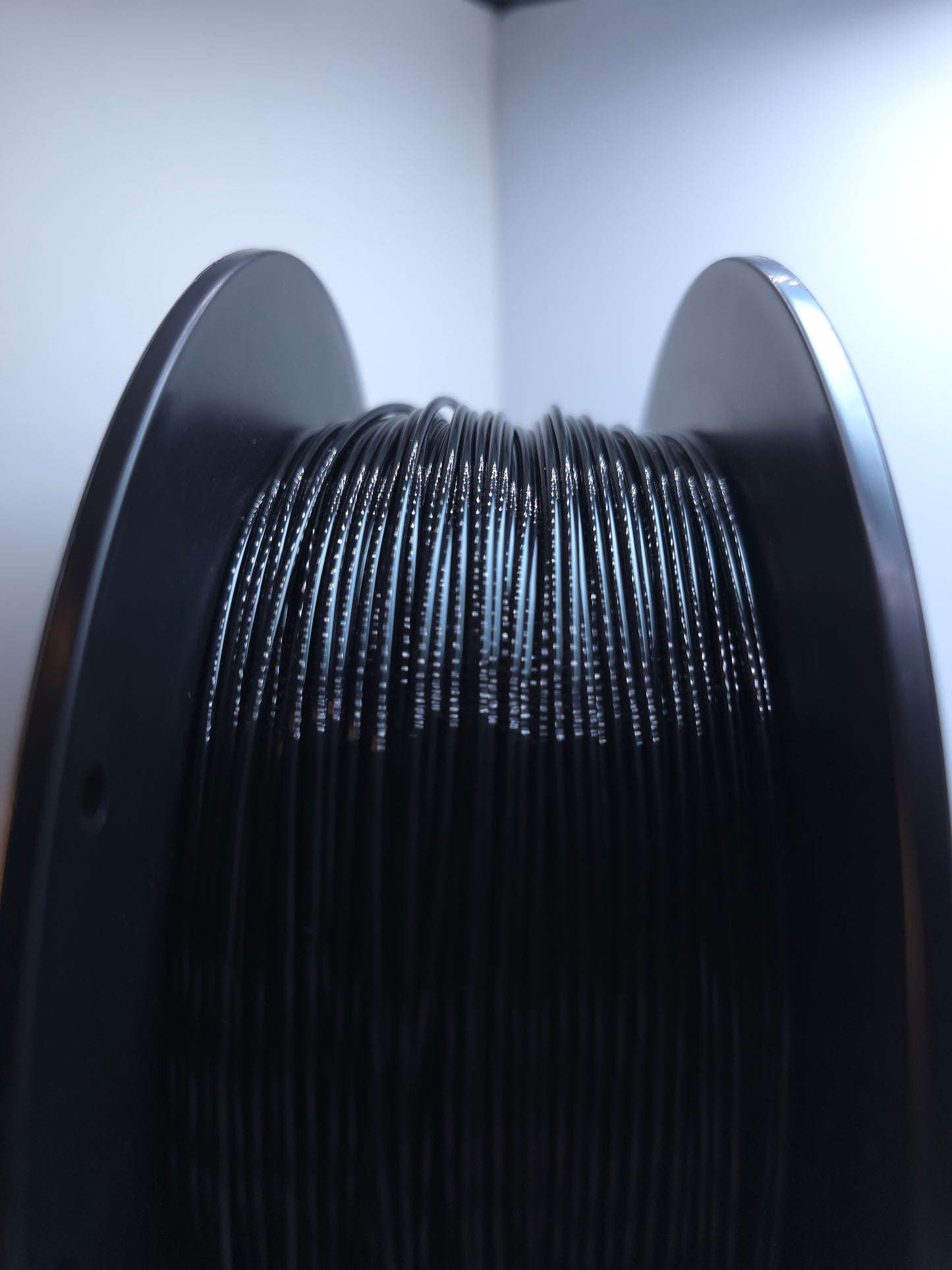

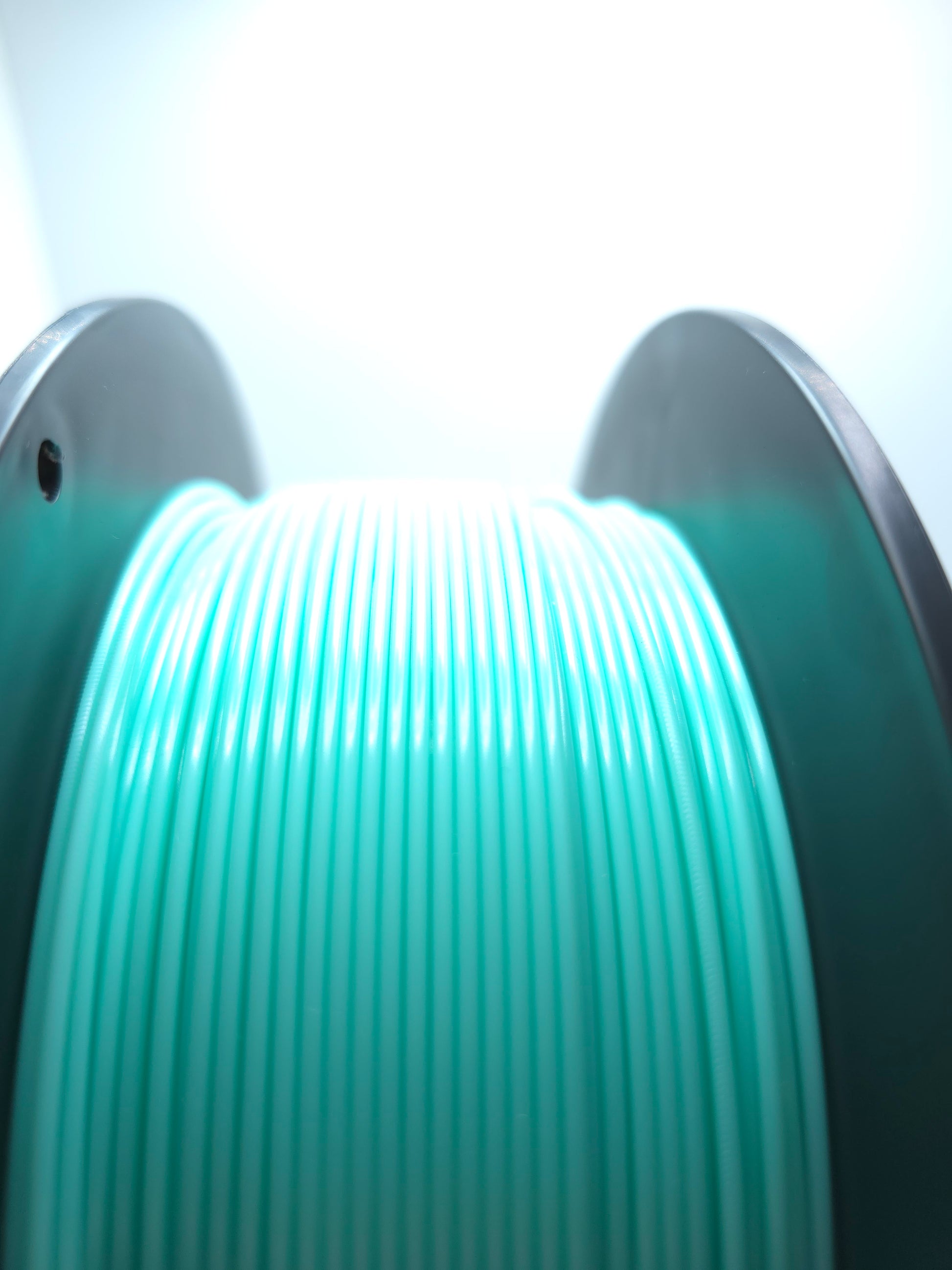

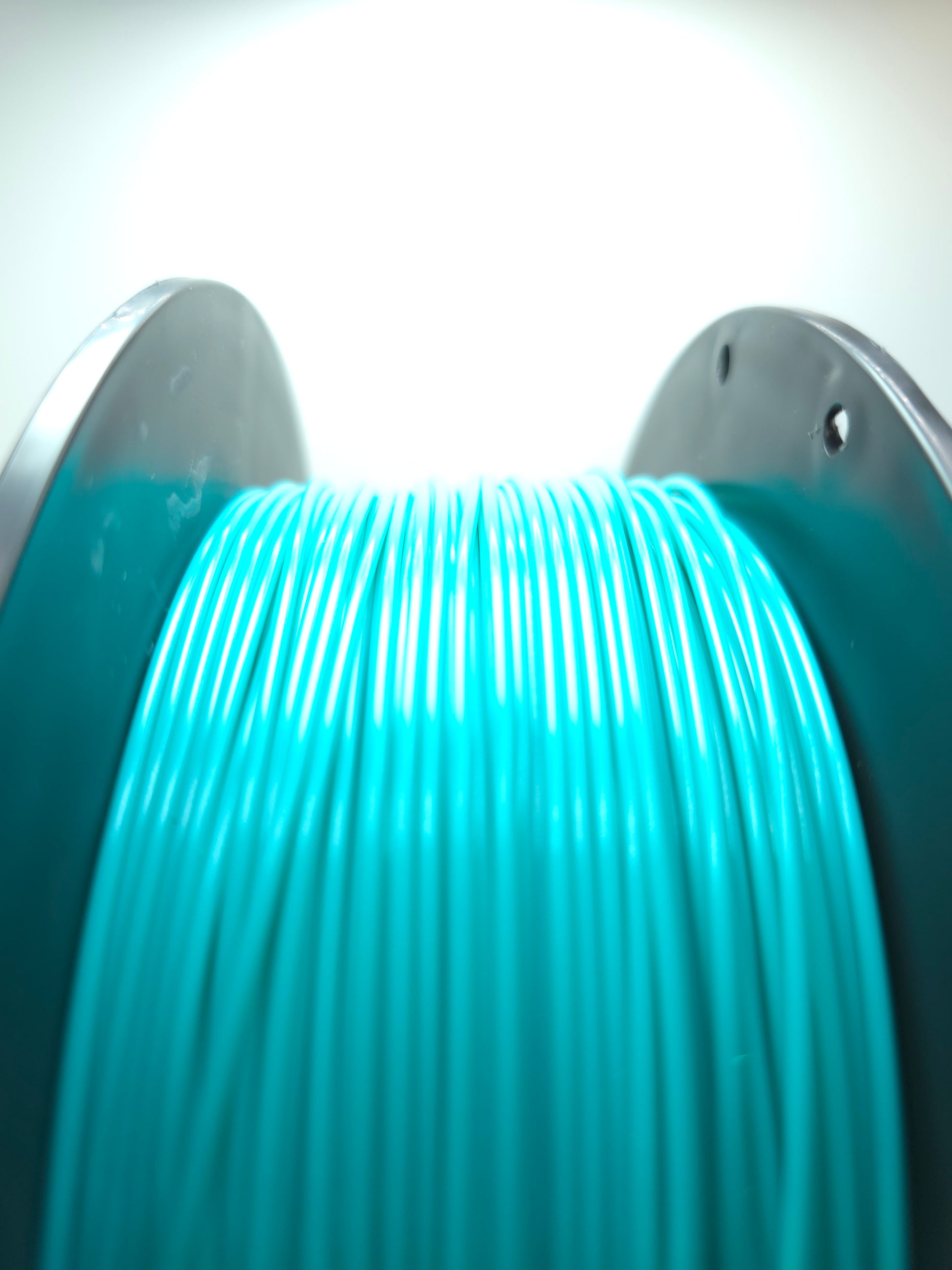

The PETG filament product line is equipped with self-developed excellent neat winding device, with 100% neatness rate, avoiding neat and tangle-free lines, thus avoiding possible jamming and thread breakage; the larger spool inner diameter design makes the feeding of the threads smoother.

PETG Filament Recommend Settings: I recommend print the PETG filament at a nozzle temperature of 220-250°C(428-482°F), bed temperature of 75-85°C(167-185°F), printing speed of 50-100mm/s.

Spool Diameter: 8.00", Spool Width: 2.50", Spool Hub Hole Diameter: 2.20". Dimensional Accuracy +/- 0.02mm.

Technical Data

Physical Nominal Value Unit Test Method

Specific Gravity 1.27 g/cm³ ASTM D792

Water Absorption (24 hr) 0.20 % ASTM D570

Color b - Hunter 4 < 1.00 ASTM E308

Mechanical Nominal Value Unit Test Method

Tensile Strength ASTM D638

Yield 53.0 MPa

Break 26.0 MPa

Tensile Elongation 5 ASTM D638

Yield 5.0 %

Break 70 %

Flexural Modulus 2150 MPa ASTM D790

Flexural Strength 6 80.0 MPa ASTM D790

Impact Nominal Value Unit Test Method

Notched Izod Impact (23°C) 90 J/m ASTM D256

Hardness Nominal Value Unit Test Method

Rockwell Hardness (R-Scale) 116 ASTM D785

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load ASTM D648

0.45 MPa, Unannealed 74.0 °C

1.8 MPa, Unannealed 70.0 °C

Vicat Softening Temperature 83.0 °C ASTM D1525 7

Electrical Nominal Value Unit Test Method

Surface Resistivity 1.0E+16 ohm ASTM D257

Volume Resistivity 1.0E+15 ohm·cm ASTM D257

Dielectric Strength 8 16 kV/mm ASTM D149

Dielectric Constant ASTM D150

1 kHz 2.60

1 MHz 2.40

Dissipation Factor ASTM D150

1 kHz 5.0E-3

1 MHz 0.023

Flammability Nominal Value Unit Test Method

Flame Rating UL 94

1.00 mm HB

1.50 mm HB

3.00 mm V-2

Optical Nominal Value Unit Test Method

Gloss (60°) 159 ASTM E308

Refractive Index 1.570 ASTM D542

Transmittance 89.0 % ASTM D1003

Haze < 1.0 % ASTM D100